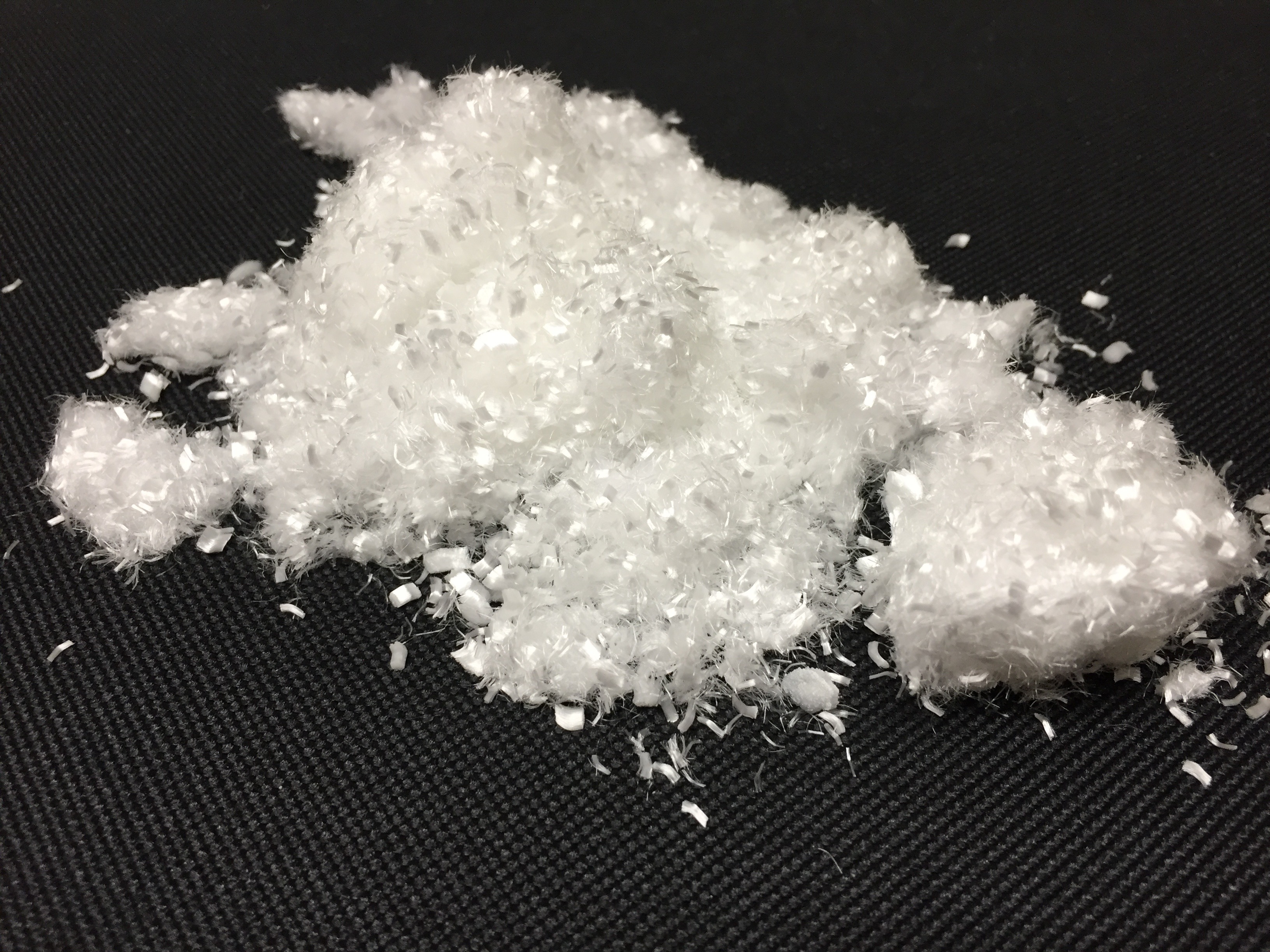

FORTA Super-Sweep® fiber has a long history of solving difficult hole-cleaning problems under a wide variety of drilling conditions. Super-Sweep Fine fiber continues that successful tradition, while adding new and varied applications for use in both drilling fluids and cement. Like Super-Sweep, Super-Sweep Fine is a 100% virgin synthetic fiber that is specially treated to suspend in any and all drilling fluids, to create carrying capacity without changing the viscosity of the fluid. However, this shorter and finer version is considerably more compatible when down-hole tools are being used, and more user-friendly for horizontal drilling applications. More importantly, the unique fiber dimensions allow for dry-blending with cement, opening new application doors to help control circulation losses.

FORTA Super-Sweep Fine is a multi-purpose fiber, used to clear debris from drilling fluids and lead cement, and/or act as a cohesive LCM binder in cement. The fiber’s ability to uniformly mix and suspend in these wet or dry mediums creates a variety of benefit areas, while remaining manageable and user-friendly in the process. The shorter, tighter fiber bundle allows for higher fiber concentrations in both fluids and cement, which offers increased benefits in both areas. For instance, higher concentrations may be used where MWD tools are being used, which allows for more effective hole-cleaning. And higher concentrations in cement create additional hardened properties that are contributed by the fiber, leading to improvements to tensile and compressive strengths, toughness, and ductility.

Like the original Super-Sweep® fiber, Super-Sweep Fine® is easily dosed and added to any drilling fluid system. As a hole-cleaning agent, concentrations range from ¼ to ½ pounds per barrel of fluid. The fiber and cuttings and/or millings are removed by the shaker or discharged to the reserve pit.

When used as a cement LCM additive, dosages of 1/8 to ½ pounds per sack of cement are possible without concerns of plugging or balling. Both Super-Sweep® and Super-Sweep Fine® can be added to cement on the fly, however Super-Sweep Fine® can also be dry-blended and pneumatically transferred at concentrations up to ½ pound per sack of cement. Fiber concentrations are dependent on the level of cuttings-suspension or LCM-capacity desired in given conditions.

Super-Sweep Fine is conveniently packaged in 15 or 30-pound easy-open bags, as well as 15-pound boxes. The plastic bag packaging also allows for a denser cube for pallets and containers, and maximizes freight and storage efficiencies. These bags can be quickly added to the fluid system in pill form through the hopper. Simply mix the desired concentration of Super-Sweep Fine into a pre-determined volume pill and circulate while continuing normal operations. The Super-Sweep Fine fibers and captured solids are easily removed by the solids control equipment.